The emergence of 3D printing has completely transformed the landscape of smart device manufacturing. This technology has brought about a seismic shift in the industry, revolutionizing the way smart devices are designed and manufactured.

The integration of 3D printing technology has not only opened up new doors for innovation but has also made previously unachievable possibilities a reality. As we explore the impact of 3D printing on smart device manufacturing, we discover a plethora of advantages and challenges that are shaping the future of this groundbreaking revolution.

Evolution of 3D Printing Technology

The evolution of 3D printing technology has been remarkable in recent years, completely transforming the manufacturing process of smart devices. The advancements in 3D printing have allowed for the production of highly intricate and personalized components with unmatched accuracy.

One significant development is the expansion of materials used in 3D printing, including advanced polymers, metals, ceramics, and biomaterials. These diverse materials have greatly enhanced the capabilities of 3D printing, making it possible to create durable and functional parts that are essential for the performance and visual appeal of modern smart devices.

As a result, 3D printing has become a crucial component in the manufacturing of smart devices, offering a cost-effective and efficient method for producing complex components.

Impact on Smart Device Design

The design process for smart devices has been revolutionized by the integration of 3D printing technology. This technology allows for unprecedented levels of customization and innovation. With 3D printing, smart device customization has reached new heights. Highly personalized components can now be produced to cater to individual preferences. This flexibility in design has become a characteristic of smart device manufacturing. It enables rapid iteration and customization based on user feedback and market trends.

The use of 3D printing has also made it possible to create intricate and complex designs. These designs were once challenging to manufacture using traditional methods. This technological advancement has opened doors to a new era of innovative and aesthetically pleasing smart devices.

Advantages for Manufacturing Processes

3D printing technology brings numerous advantages to manufacturing processes, enabling efficient production and enhanced product quality. One key benefit is cost efficiency. By allowing for the creation of complex designs in a single production process, 3D printing reduces material waste and labor costs. This streamlined approach minimizes the need for multiple parts and assembly, ultimately lowering overall manufacturing expenses.

Another advantage of 3D printing is its ability to facilitate rapid prototyping, which accelerates the product development cycle. It enables quick and cost-effective production of prototypes, allowing for iterative testing and refinement. This significantly speeds up the design process by reducing time-to-market.

Additionally, the ability to swiftly produce and test prototypes enhances the overall quality of smart devices by enabling thorough testing and optimization.

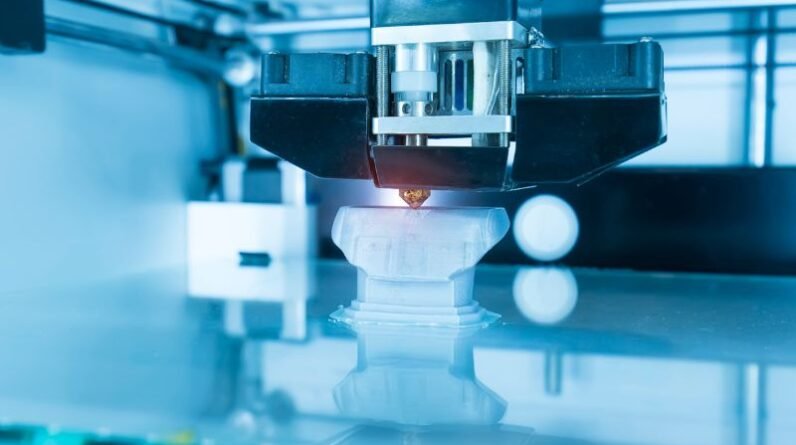

Integration of 3D Printing in Production

Integrating 3D printing into the production process revolutionizes manufacturing by enhancing efficiency and flexibility while reducing costs.

3D printing is widely used in prototyping, allowing for rapid iteration and refinement of designs without the need for expensive tooling. This significantly speeds up the product development cycle, enabling faster time-to-market for smart devices.

3D printing enables cost-effective production of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. By integrating 3D printing into the production line, manufacturers can reduce lead times, minimize material waste, and customize products more easily, ultimately leading to improved overall operational efficiency.

The seamless integration of 3D printing technology offers manufacturers a competitive edge in the rapidly evolving landscape of smart device manufacturing.

Future of 3D Printing in Smart Devices

As we look ahead to the future of 3D printing in smart devices, it’s clear that the technology has the potential to revolutionize design and production processes. The future of 3D printing in smart devices is full of promise, driven by advancements in materials and design flexibility.

Here’s what we anticipate:

– Advancements in Materials:

New materials that offer enhanced properties such as conductivity and durability will enable the creation of more advanced and efficient smart devices. Additionally, the ability to 3D print with sustainable materials will contribute to more eco-friendly manufacturing processes.

– Cost Efficiency and Sustainability Benefits:

3D printing will lead to cost-efficient production by reducing material wastage and energy consumption. The technology’s potential to create complex designs with minimal waste aligns with the growing focus on sustainable manufacturing practices.

Conclusion

3D printing has revolutionized smart device manufacturing, reshaping the design and production processes. Its advancement has brought numerous benefits to manufacturing and seamlessly integrated into production.

Looking ahead, 3D printing will continue to be crucial in driving innovation and development of smart devices, opening up limitless possibilities and advancements in the industry.